動力電池導熱矽膠片系列,是專為新能源汽車電池散熱而研發設計的超輕超低密度的動力電池導熱矽膠片,是新的一代高導熱低熱阻的產品,有別於傳統導熱矽膠片與導熱方案,已成為新能源汽車廠商新寵。動力電池導熱矽膠片系列產品具有高變形彈性和良好壓縮比,適用於大型機構設計公差,采用特殊的超薄玻纖布雙層結構,增加可操作性與耐用性,無論是沖壓打孔,條式,畸形設計都不會破碎和變形。動力電池導熱矽膠片是單面自粘矽凝膠,自粘性永不退卻,在銅表面上沒有腐蝕,完全無毒綠色環保產品,符合國際要求。

Power battery thermal conductive silicone sheet series is an ultra-light and ultra-low-density power battery thermal conductive silicone sheet specially developed and designed for the heat dissipation of new energy vehicle batteries. It is a new generation of high thermal conductivity and low thermal resistance products, which is different from traditional thermal conductive silicone sheets. The heat conduction solution has become the new favorite of new energy vehicle manufacturers. Power battery thermal conductive silicone sheet series products have high deformation elasticity and good compression ratio, which are suitable for large-scale mechanism design tolerances. They adopt a special ultra-thin glass fiber cloth double-layer structure to increase operability and durability. Style, deformed design will not be broken and deformed. The thermal conductive silicone sheet for power battery is a single-sided self-adhesive silicone gel. The self-adhesiveness never fades. There is no corrosion on the copper surface. It is a completely non-toxic and environmentally friendly product that meets international requirements.

動力電池導熱矽膠片系列,是專為新能源汽車電池散熱而研發設計的超輕超低密度的動力電池導熱矽膠片,是新的一代高導熱低熱阻的產品,有別於傳統導熱矽膠片與導熱方案,已成為新能源汽車廠商新寵。動力電池導熱矽膠片系列產品具有高變形彈性和良好壓縮比,適用於大型機構設計公差,采用特殊的超薄玻纖布雙層結構,增加可操作性與耐用性,無論是沖壓打孔,條式,畸形設計都不會破碎和變形。動力電池導熱矽膠片是單面自粘矽凝膠,自粘性永不退卻,在銅表面上沒有腐蝕,完全無毒綠色環保產品,符合國際要求。

Low density, high deformation, suitable for low pressure applications, reinforced with glass fiber cloth

低密度、高變形量、適合低壓應用、具有玻纖布補強

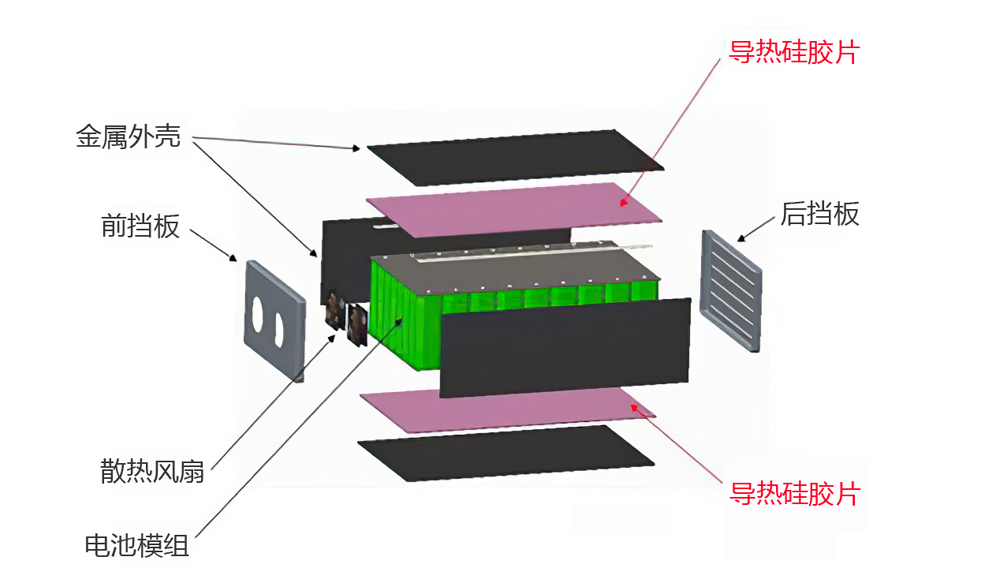

New energy vehicle battery pack

新能源汽車電池包

| unit | LBD-P10LD | LBD-P15LD | LBD-P20LD | method | |

| 颜色 Color | Pink / Yellow | Pink /Pink | Pink / White | visual | |

| 补强材 Reinforcement Carrier | Fiberglass | Fiberglass | Fiberglass | ||

|

单面粘性 Inherent Surface Tack (1-/2- sided) |

1-side | 1-side | 1-side | ||

| 厚度 Thickness | mm | 0.3~5.0 | 0.3-5.0 | 0.3-5.0 | ASTM D374 |

| 密度 Density | g/cm3 | 1.6 | 1.7 | 1.9 | ASTM D792 |

| 硬度 Hardness | ASKER C | 10 | 15 | 20 | ASTM D2240 |

| Shore 00 | 30 | 40 | 50 | ||

| 使用温度 Application temperature | ℃ | -60~150 | -60~150 | -60~150 | |

| 抗拉强度 Tensile Strength. | psi | >300 | >300 | >300 | ASTM D412 |

| 伸长率 Elongation | % | <10 | <10 | <10 | ASTM D412 |

| 损失比重 Total mass loss | % | <0.5 | <0.5 | <0.5 | ASTM E595 |

| 击穿电压 Dielectric breakdown | KV/mm | >10 | >10 | >10 | ASTM D149 |

| 体积电阻 Volume resistivity | Ohm-m | >1011 | >1011 | >1011 | ASTM D257 |

| 导热系数 Thermal Conductivity | W/m*K | 1.0 | 1.5 | 2.0 | Hotdisk |

|

热阻抗 Thermal impedance@20psi,1.0mm |

℃-In2/W | 1.03 | 0.80 | 0.6 | ASTM D5470 |

|

热阻抗 Thermal impedance@50psi ,1.0mm |

℃-In2/W | 0.83 | 0.65 | 0.48 | ASTM D5470 |

|

低分子矽氧烷含量 Siloxane Volatiles D4~D20 |

% | <0.01 | <0.01 | <0.01 | GC-FID |

| 阻燃性 Flammability | V-0 | V-0 | V-0 | UL94 |